Types of Combustion Engines

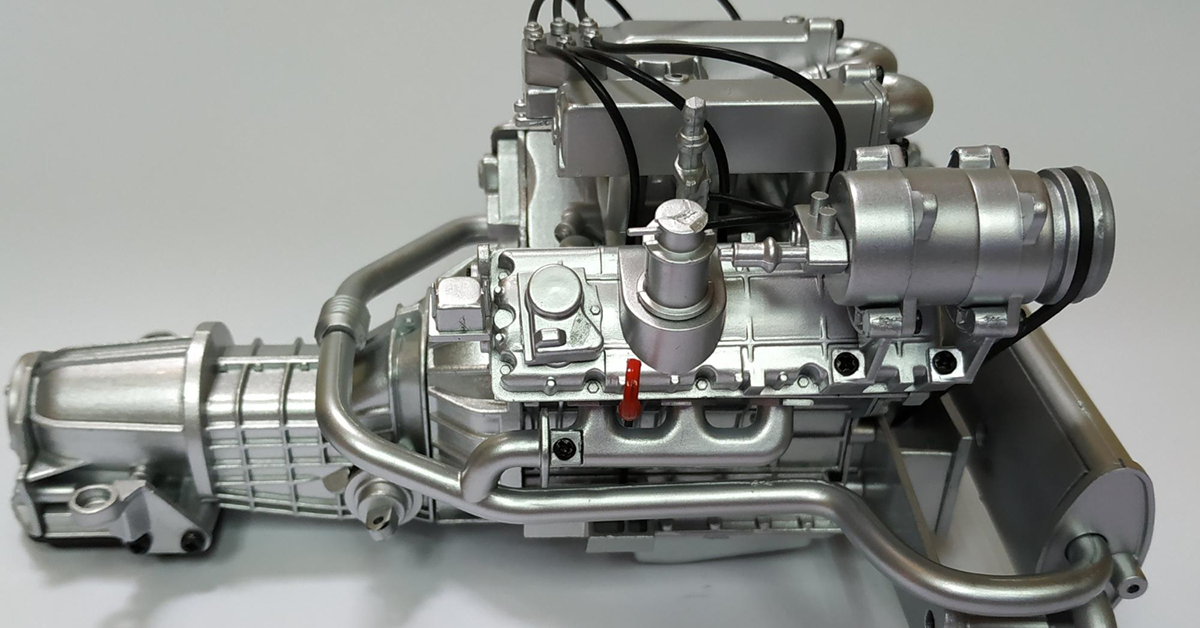

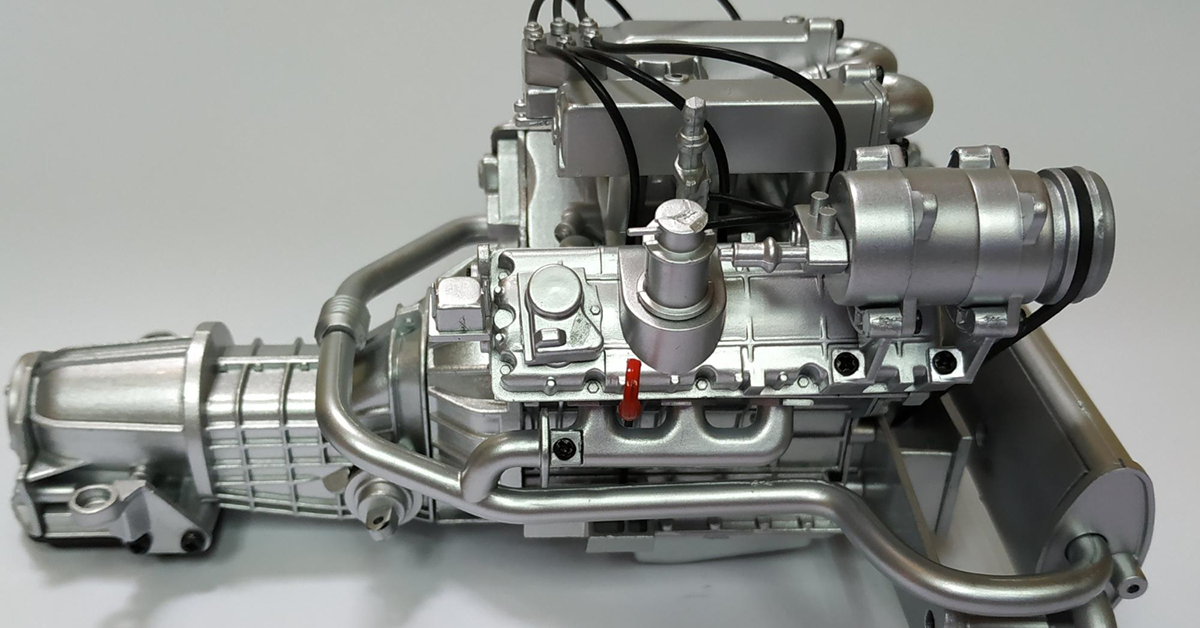

Introduction to Combustion Engines Combustion engines are the powerhouse behind many of our everyday machines, from cars to airplanes. Understanding the various types can give […]

Introduction to Combustion Engines Combustion engines are the powerhouse behind many of our everyday machines, from cars to airplanes. Understanding the various types can give […]

Copyright © 2025 | WordPress Theme by MH Themes